Towel Drier production

Raw Material

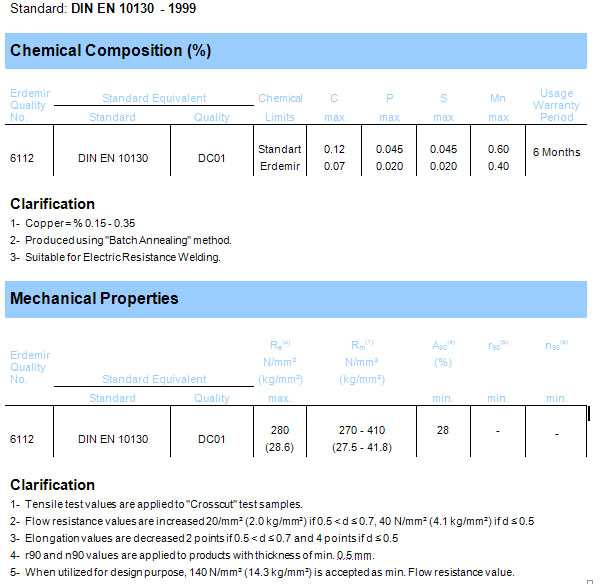

High paint retention ability and durability is a major property of steel types used in production of residential heating appliances such as Steel Panel Radiators and Towel Driers. Besides, based on production line characteristics, low/high current welding capability is also crucial. The steel according to DIN EN 10130 used in production of Caloree products posseses abovementioned chracteristics.

Chemical composition and mechanical properties of steel utilized in Caloree Steel Panel Radiator and Steel Towel Drier production is as following:

Stages of Production

-

During production, burr-free pipe cutting machine prevents formation of aesthetical defects in the form of steel burr. Thus, the risk of sawdust remain in the later stages of production is eliminated.

-

At this stage of production, profiles are cut using CNC controlled profile-cutting machine. This machine allows cuts with precision of 1/10 of a millimeter and has very high production capacity.

-

At this stage of production the profiles are bored with specific diameter and at specific intervals. Precision positioning feature of this machine allows sensitive boring with precision of 1/10 millimeter in terms of diemeters and intervals according to consumer demand.

-

At this stage, pipe end shirring machine performs precision tube calibration before passing to grouping.

-

Polishing applied at pipes results in ideal brightness and surface smoothness of value lower than 0.20 Mikro Ra. The polishing machine used in our production is procured from German technology provider, Löser.

-

Profiles, passing thought 8 different stages of polishing, achieve ideal brightness and surface smoothness of value lower than 0.10 Mikro Ra

-

At this stage, before furnace welding process, pipes and profiles are mechanically attached to one another. This attachment provides almost zero defect furnace welding, thus achieving better leakproofing in comparison to products with manual welding.

-

Furnace welding is a latest technology used in wedling process. The furnace welding machine used in our production is procured from German technology provider, Mahler. After furnace welding , the products acquire excellent mechanical properties.

-

After furnace welding all products are tested under 13.5 bar pressure. Only products passing through 100% leakproofing test continue to next stages of production.

-

Fully automatic painting line is used in our production for the achievement of the best product coatings. Special robotic spray guns used in the process result in paint cover which is durable to salt test more than 500 hours.

Chrome Coating

Electrolisys coating technology is used in Caloree Steel Towel Drier chrome plating process. The main principle in this technology is using the product to be coated as cathode and the substance that will coat the product filled in plating pool as anode. Clean product surface is the main factor in attaining durable coating on product metal surface in chrome coating prosedure. This is why chrome coating process of Caloree Towel Driers starts with polishing prosedure. Polishing applied at pipes results in ideal brightness and surface smoothness of value lower than 0.20 Mikro Ra. Profiles, passing thought 8 different stages of polishing, achieve ideal brightness and surface smoothness of value lower than 0.10 Mikro Ra. Mechanical acidic degreasing is applied to products for wax and oil waste cleaning. After rinsing the product passes through mechanical basic and electrical degreasing. The product is rinsed again and coated with primary matt nickel. Then the product goes through chemical oxide removal process and rinsed for the third time. Later, copper coating and bright nickel coating is applied to product and the product is being rinsed after each stage. Finally products go through chrom activation process which is also known as smoothing and become ready for chrome coating. After chrome coating stage the products go through final rinsing, tested and dried. Chrome coating makes towel driers visiually more attractive and stylish. It also increases the durability of towel driers against corrosion, wearing and tearing.

Packaging

The products are being packed carefully to prevent damage during transportation. Coloured products are packed using orange coloured caps for water passages that prevent groove from wreckage. The product and assembly accessories are put into nylon bag and reinforces by plastic tampons on edges. Later the product is put into cardboard box that exacly fits the sizes of product. Products in cardboard boxes are vertically aligned on pallets, fixed together and wrapped by PVC film to avoid damage on cardboard packing. This kind of packing prevents the product from being damaged due to wobble and friction during carriage.

Chrome coated products are packed using bubbled film bags instead of nylon bags.

Traceability

The system used in Caloree Steel Towel Drier production facility markes each product with a distinctive number code at early stage of production. Serving as identity code, this marking facilitates tracebility of products during production, before and after sales.

WE OFFER

our facts

- 52 Happy customers

- 48 export countries

- 17213 successfull loadings

- 15 years of experience