Radiator Production

Raw Material

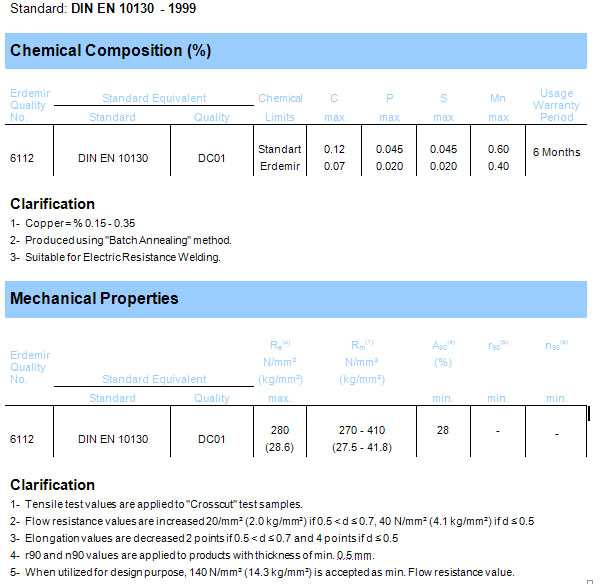

High paint retention ability and durability is a major property of steel types used in production of residential heating appliances such as Steel Panel Radiators and Towel Driers. Besides, based on production line characteristics, low/high current welding capability is also crucial. The steel according to DIN EN 10130 used in production of Caloree products posseses abovementioned chracteristics.

Caloree Steel Panel Radiators are produced according to EN 442 Norm. The panel steel thickness is 1,20 mm and convector steel thickness is 0,36 mm.

Chemical composition and mechanical properties of steel utilized in Caloree Steel Panel Radiator and Steel Towel Drier production is as following:

Production Line

Caloree Steel Panel Radiator factory utilizes two fully automated production lines. Our production lines with total yearly production capacity of 2 millions meters are produced by renowned European technology provider, Leas. We use top quality metal forming presses and painting lines.

The production is fully automatic, none of production stages in the line utilizes labor force. All products are tested under 13 bar pressure. Only products passing through 100% leakproofing test continue to next stages of production.

Packaging

Passing quality control at each stage of production Caloree Steel Panel Radiators are packed after final control, visual inspection. After packing using side cardboards products pass thought shrink packing process. Later the products are stowed on wooden pallets that fit the product sizes. Radiators on pallets are wrapped by PVC strap to prevent possible damage due to wobble and friction. Tension belts and airbags used to support the pallets in the vehicle minimize the possibility of damage during transportation.

WE OFFER

our facts

- 52 Happy customers

- 48 export countries

- 17213 successfull loadings

- 15 years of experience